TRS High Duty, HD Series Boom Systems lead the way for large scale and demanding mining operations

With over 20 years of experience designing rockbreaker boom systems, TRS engineers have worked closely with customers and mine site personnel in some of WA’s harshest mining operations to address reliability and availability concerns in high duty, hardworking applications.

Re-designed from the ground up, TRS HD Series Boom Systems represent the first significant development in fixed plant rockbreaker boom systems in over a decade. TRS HD Booms are high-quality, Australian engineered products which are specifically designed to operate faster and with longer reach and larger hammers than previous generations of boom systems.

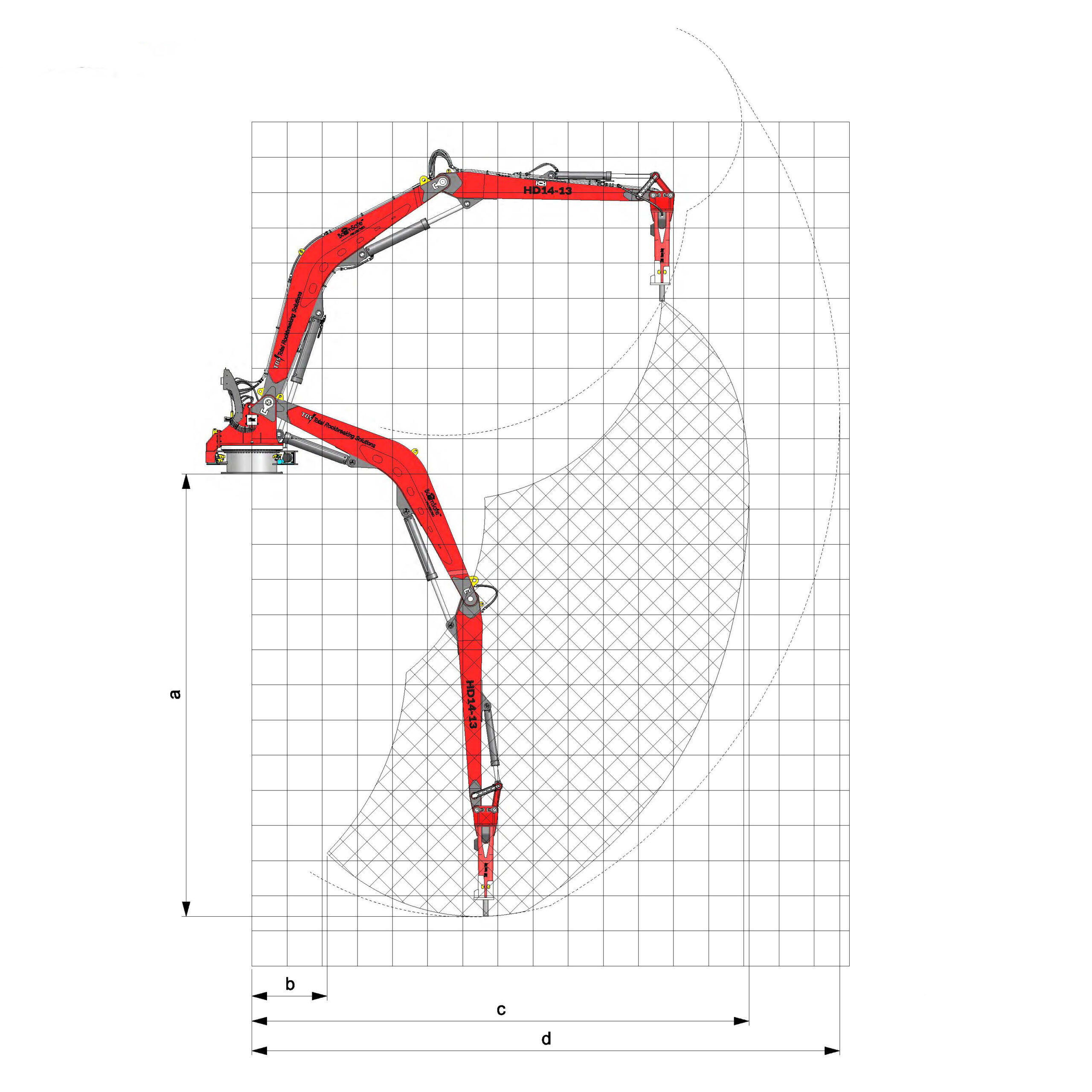

To meet the needs of modern mines, TRS HD series include 7 models spanning from 22.5 to 25.8 tonne with reaches up to 17.8 metres and have key features that set them apart from the rest in terms of performance, reliability and ease of maintenance, all of which reduce downtime and costs.

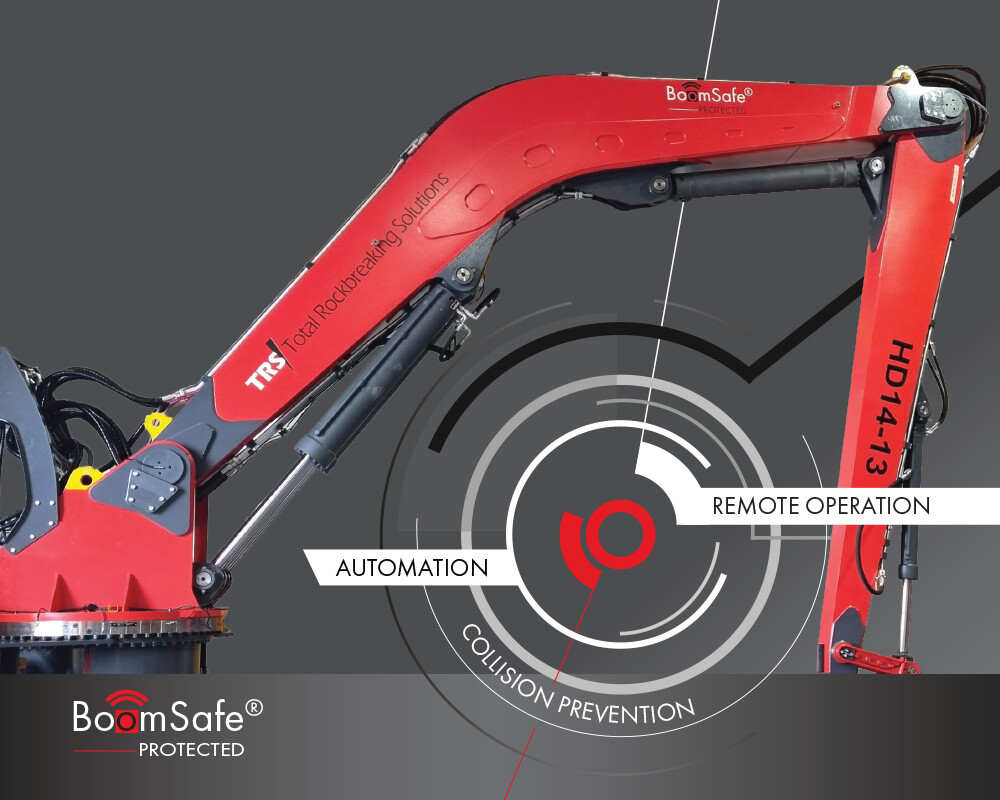

Incorporating our industry leading BoomSafe® control and automation system, TRS Boom Systems are supplied with features such as collision avoidance and automated movements, with options for remote multi-user operation available.

Performance

Increased movement speeds and longer reach booms means the HD range can cater for even the most demanding applications. Combined with the our ‘Zero-Tension’ hose support, ‘Clean-Fill’ lubrication system and TRS BoomSafe® for reliable boom control and automation will ensure significant increases in availability and reliability can be achieved whilst also maximising the overall life of the asset.

Safety

Load holding valves are built into all cylinder barrels to protect them from external damage and safety-rated, fail safe, secondary slew sensors are available in addition to the primary left and right slew sensors. Energy absorbing mechanical stops are also available as an option to provide an absolute slew limit and are strongly recommended for remotely operated boom systems.

Easy Maintenance

Induction hardened, hard chromed pivot pins with built-in extraction facilities, standardised components across the HD range and an extensive library of proven stands / frames for safe and efficient hammer and hammer tool changing are just some of the ways to keep maintenance costs and downtime to a minimum.

Rockbreaker control and automation

The TRS HD Booms operate faster, have longer reach and carry larger hammers than previous generations of boom systems on the market.

With increased performance and reliability, as well as several contemporary enhancements, including single touch DEPLOY and PARK commands, ensure routine movements at the start and end of every operation are carried out at maximum speed and without risk of collision with surrounding infrastructure.

The range includes the TRS BoomSafe® Control System fitted as a standard feature to provide reliable, proven automated movements and collision prevention. The systems can be enabled with remote operation capabilities, which allow multiple rockbreaker boom systems to be controllable from a single workstation.

Download the information sheet for details.

TRS HD Series, BoomSafe® Protected Boom Systems and TRS Hydraulic Power Units

Features and Benefits

- Manufactured in Australia under strict quality control by our experienced team.

- Can be customised to comply with any client or site technical specifications.

- High flow control valves and large diameter pipes and hoses for higher speed of operation i.e., reduced PARK and DEPLOY times.

- Compatible with large and extra-large rockbreakers to achieve maximum productivity.

- Dual row ball bearing slew with protected internal gear and dual heavy-duty purpose-built hydraulic drive system.

- Heavy-duty linkage assembly on head bracket for maximum rockbreaker tilt and raking force for quicker grizzly or crusher clearing.

- Heavy-duty cylinders with friction welded cylinder rod ends and load holding over-centre valves on ALL cylinders.

- TRS BoomSafe® boom control system fitted as standard to increase speed and safety.

- Optional heavy-duty, energy absorbing mechanical slew stops and dual slew sensing arrangement.

For standard and optional features of each model, follow the model links above.

Increase safety with smart boom technology

Increasingly, mine operators are turning to technology and remote operation to reduce the exposure to risk for operators and nearby personnel.

Developed specifically for hydraulic boom systems BoomSafe® combines automated movement sequences, collision prevention and it allows remote operation of your boom systems via a plant network at any location in the world.

BoomSafe® is the most advanced remote operator controlled, collision prevention and automated movement system on the market and you can have it factory fitted on new Boom Systems or retro-fitted to your existing Boom. READ MORE.

4 things to consider before buying a fixed boom system

Pedestal mounted hydraulic boom systems are typically installed above crusher inlets or ROM hoppers and grizzly screens to minimise downtime and avoid damage caused by oversize product blocking chutes or crusher inlets.

To maximise the return on this investment and ensure optimum performance, it is important to consider the following before purchasing a new pedestal rock breaker boom system:

- A correctly sized hydraulic rockbreaker

- The Boom size and reach

- Position, elevation and working slew angle of the boom

- Safety systems, automation, remote operation and spare parts

Download the information sheet for details.