Efficient compaction for a wide range of applications

Australia’s best known and most reliable excavator mounted compactor plates, PneuVibe are efficient and safe solution for a wide range of applications, from working in narrow trenches to large backfill operations.

With optional clamping devices you can also drive posts from 50mm to 300mm in diameter.

The range consists of eight models, all of which deliver a class-leading frequency and centrifugal force-to-weight ratio, providing the most efficient means for vertical and inclined compaction.

High Performance

The impulse force generated from the vibration and static down pressure enables you to compact most soil types to required density levels in efficient lift capacities.

Minimised Vibration to the Boom

Patented rubber design ensures increased rubber mounts life and minimises vibration transmitted to the boom.

Simple to connect

PneuVibe compactor plates can be simply connected to your machine’s existing hydraulics.

Simple to connect and operate

PneuVibe compactor plate can be simply connected to your machine’s existing hydraulics whether your machine is a small backhoe or a large crawler excavator. If you have existing hydraulic rockbreaker piping on your machine, connecting the compactor plate is even easier.

Operating is simple as the vibration produced by the rotating eccentric combined with the down pressure of the carrier generates impulse force that can be placed wherever your boom will reach.

All Pneuvibe compactor plates include as standard a priority flow valve which protects the hydraulic motor from excess oil flow from the excavator. This feature allows the compactor to be swapped between excavators without having to worry about checking the oil flow to the compactor, perfect for a hire companies with many excavators.

PneuVibe Compactor Plates

Follow the link for specifications.

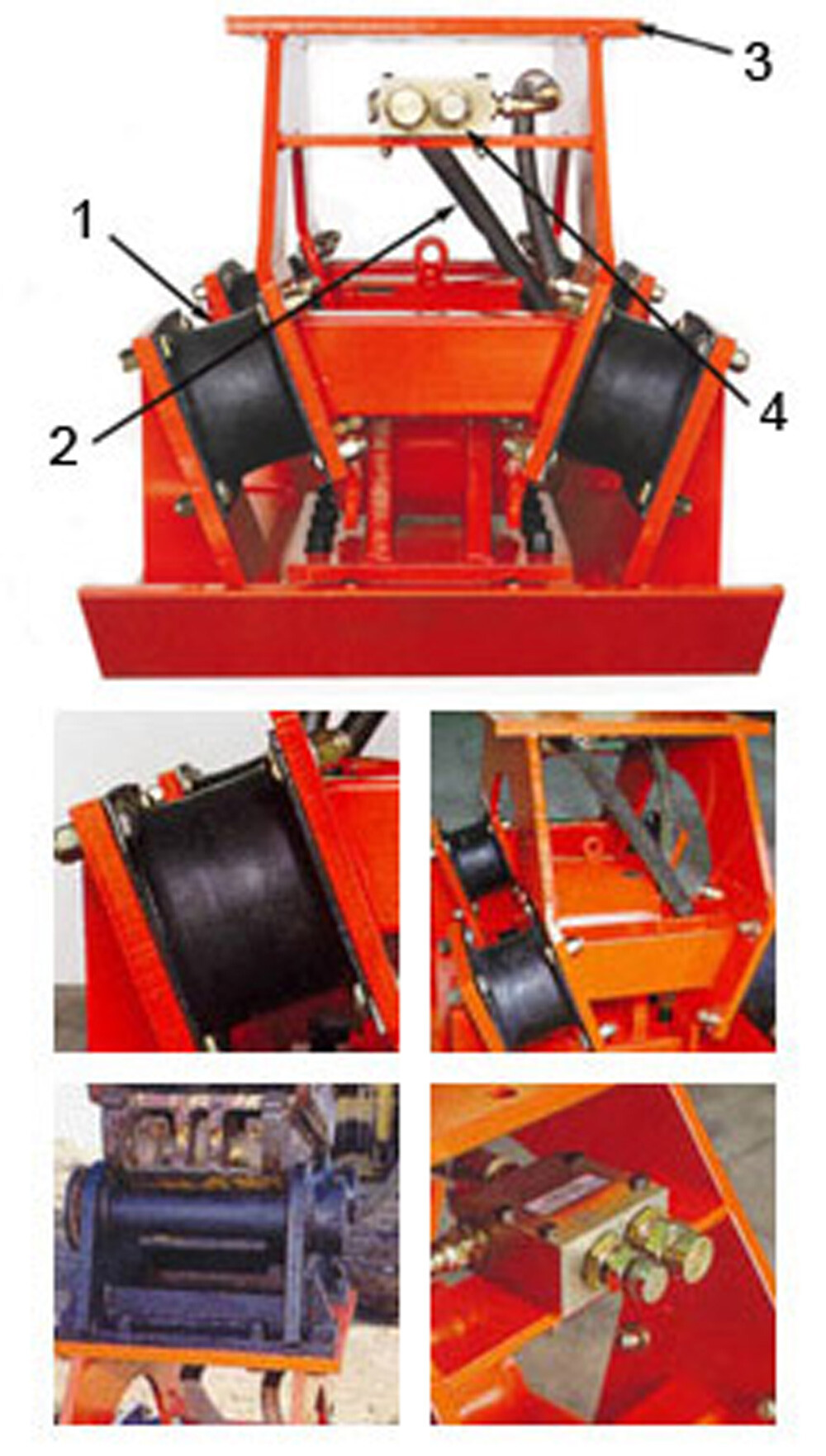

1.

PneuVibe’s patented system ensures increased elastomer life and minimises vibration transmitted to the boom, thus reducing wear on the pins and bushes of the excavator. Rubber vibration mounts are angled to the base so that the pressure exerted by the boom on the top plate causes the mounts to convert from a shear to a compression mode.

2.

Protective cradle prevents the hydraulic motor and hoses being snagged or damaged on trench walls and hoses are covered with an anti abrasion wrap for maximum flexibility and durability.

3.

Direct attachment to existing hydraulic hammer mounting heads saves time and is ideal for use with quick hitch arrangements. A multi-setting, 360º swivel head attachment is also available.

4.

Built-in priority valve system monitors the oil flow, providing the correct volume to obtain maximum performance by the compaction plate and avoiding damage to the hydraulic motor due to excessive flow.