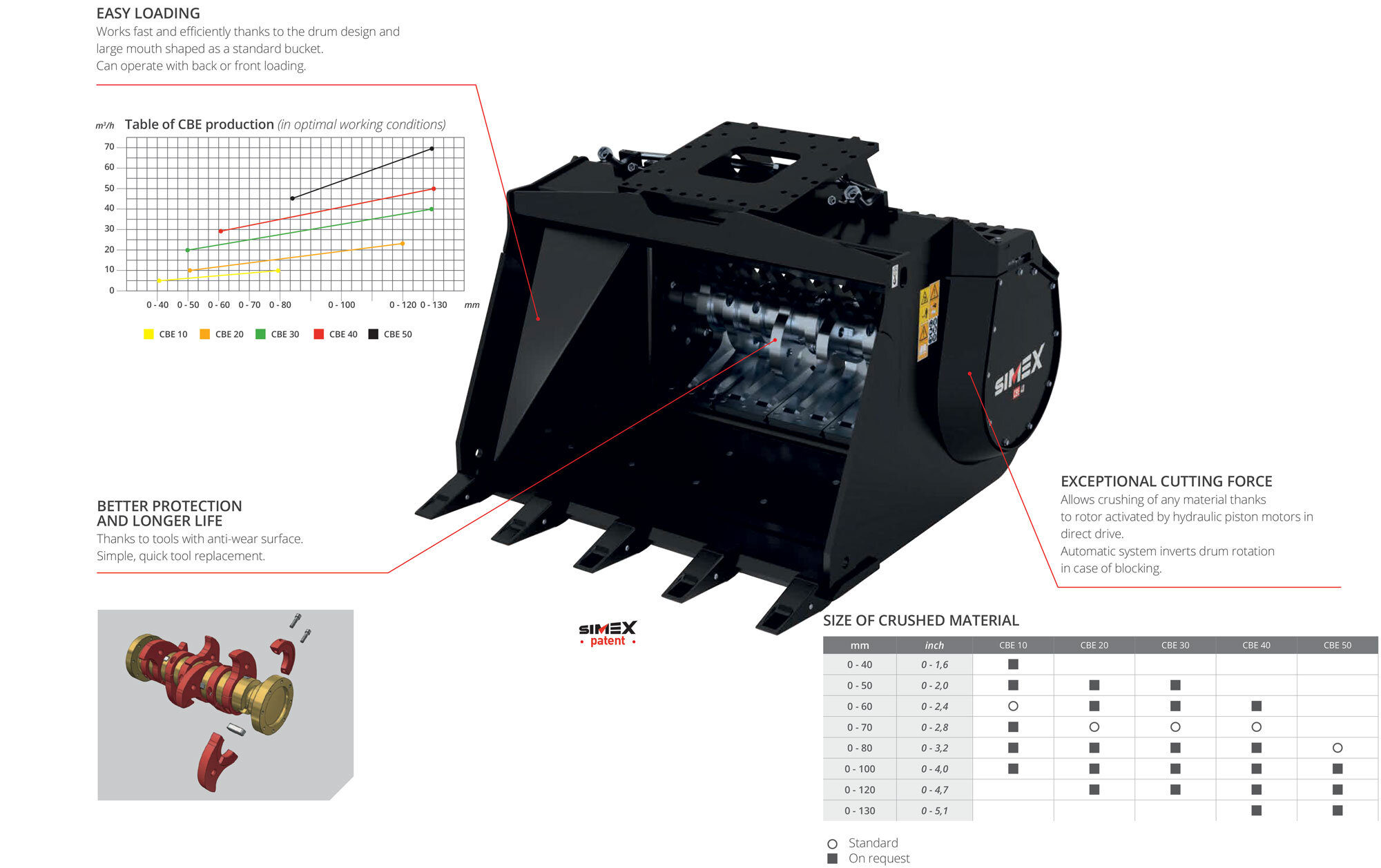

Simex Crusher Buckets turn any crushable waste material into usable material onsite

Simex Crusher Buckets CBE range for excavators are designed to reduce the volume of aggregates directly on site.

The exceptional cutting force allows any crushable waste material such as bricks, concrete, glass, reinforced concrete, natural aggregates, tiles and asphalt slabs to be crushed that can then be reused on a construction/demolition site. If the crushed material cannot be utilised on site it can be taken to the tip but with improved efficiency, as the crushed material takes up less space than uncrushed, utilising the full capacity of the truck.

High Performance

The exceptional cutting force allows any crushable material to be crushed.

Low Noise and Vibration

Ideal for crushing reinforced concrete and demolition waste even near existing infrastructure and other sensitive areas.

Low Maintenance

Anti-wear tools ensure better protection and longer life.

Simex Crusher Buckets – exceptional cutting force

Simex CBE crusher buckets feature a rotor system where the rotor with teeth is activated by high-displacement radial piston hydraulic motors in direct drive. This delivers an exceptional cutting force and ensures optimal performance when working with iron, rock, soil and deformable parts.

Simex patented automatic system inverts rotation of the drum in case of blocking to ensure the operation is unaffected by the presence of earth, wet or humid materials, or iron rods.

Smex CBE crusher buckets are easy to maneuver, even in small and confined worksites and the mountable crusher bucket models are available for excavators of 8 – 55 tonnes. See the link below for features and specifications:

Simex Crusher Buckets for excavators

The mountable Simex Crusher Bucket models are available for excavators and backhoe loaders of 8 – 55 tonnes.

See the links below for features and specifications:

Features and Benefits

Rotor system with teeth driven by hydraulic piston motors in direct drive

- Exceptional cutting force enables crushing of any material Not affected by the presence of earth, wet or humid material, or iron rods

Drum design and wide mouth

- Operating speed and efficiency

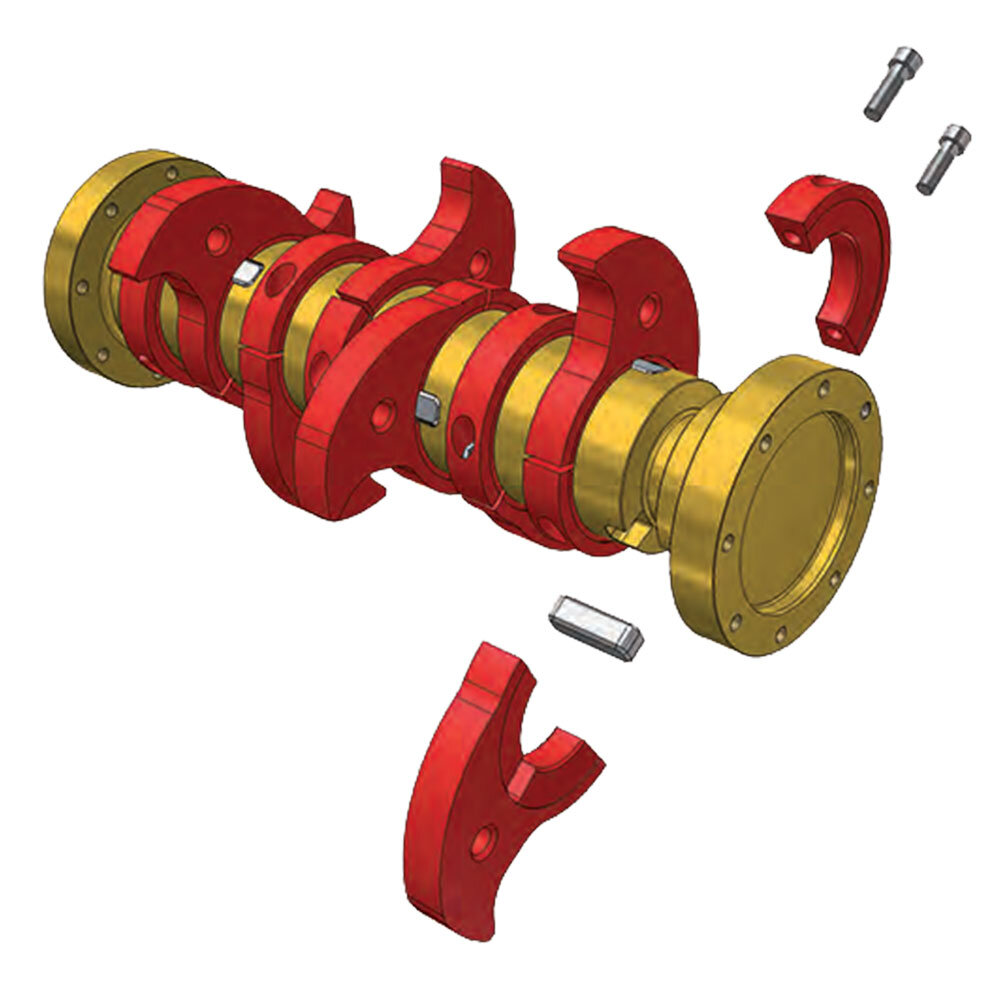

Simex patented automatic system

- Valve permitting continuous rotor rotation and an automatic system that inverts drum rotation in case of blocking ensure minimised down time with immediate resumption of work without any operator intervention

Teeth with large anti-wear surface

- Increased protection and working life

Simple and quick teeth replacement

- Minimised down time and ability to produce the crushed material in different-sized pieces