ALLU Buckets transforms Waste into Useable Material

Separating a quality product from a waste material is at the core of many civil construction and infrastructure services. For the waste sector, the sorting and screening of bulk waste material from earth works can be a difficult and cost consuming process.

ALLU Transformer buckets are purpose built for efficient material processing. Catering for applications of all sizes, and capable of processing any material that can be screened and sorted, the ALLU buckets transform materials into valuable products making processing jobs more efficient, more environmentally friendly, and minimising the need for transportation of waste or replacement materials.

ALLU Transformer buckets will process just about anything; demolition and construction waste, excavated and waste soil, contaminated soil, clay, peat, bark, compost, bio-waste, milled asphalt, glass, coal, oil shale, lime stone and several other materials. Unique design of screening blades and combs ensure the screening bucket is clog-free and maintains good production even with wet materials.

Effectively crush and recycle troublesome materials

The heavy-duty range of ALLU Screener Crusher Buckets are purpose built to meet the requirements of the quarrying, demolition and recycling industries. Whilst the ALLU Transformer range offers unique productivity and efficiency benefits on soft rock and other materials, the ALLU Crusher range enables hard rock, and often troublesome demolition materials, to be effectively reduced onsite and less material sent to landfill.

Productivity

With ALLU you can process materials onsite fast and efficiently in one step. With one ALLU you can produce multiple fragment sizes.

Efficiency

Feed materials can be transformed into valuable products that can be reused onsite. This results in substantial savings in landfill, transport and replacement material costs

Performance

ALLU Tracker measures performance and tracks equipment in the field. ALLU Tracker stores information on processing time, total working time and processed tonnes and can be viewed and analysed via an easy-to-use dashboard.

Reduce waste and increase your bottom line

Over the recent years, disposing of construction waste has become a lot more expensive. Western Australia’s waste levy rate has increased from $8 per tonne in December 2014 to the current $70 per tonne and from 1 July 2024 to $85 per tonne.

It is common practice to remove fill from site, then to bring clean material back to achieve required compaction etc. This means you are paying $70/tonne in disposal costs, $2–$3/kilometre to run your truck to the waste facility, then you buy clean fill and again pay $2–$3/kilometre to bring product back to your site. This also involves considerable use of valuable time on your project.

Rather than allowing waste to become an increasing cost, you can use ALLU bucket and process your existing fill on site, thereby eliminating most of the above costs.

ALLU AC Crusher-series

ALLU Crusher is a hydraulic crushing bucket that effectively crushes and recycles demolition materials, building rubble, natural stones, asphalt materials, concrete, and construction debris. The main applications are:

- waste rock handling at quarries

- concrete waste and asphalt recycling

- demolition and construction

- bricks, ceramics etc crushing & recycling

ALLU Crusher series includes 5 different models to suit excavators from 10 to 38t.

NEW!! The Allu AC 5-17FD crusher bucket for skid steers is now available in Australia. ALLU Crusher is ideal for processing construction & demolition waste on site in urban and semi-urban job sites where space is an issue. ALLU AC5-17FD suit skid steers from 4 to 6t.

See the links below for features and specifications:

ALLU D-Series

The ALLU D-series of hydraulic screener crusher buckets for excavators and loaders are ideal for a variety of large material processing and handling tasks, from topsoil screening to utility and road works, construction waste and asphalt recycling and pipeline backfilling, just to mention a few.

ALLU D-series buckets convert your base machine into a mobile processing plant by screening, crushing, aerating, mixing, separating, feeding and loading materials onsite in a one-step operation.

See the links below for features and specifications:

ALLU DL-Series

The ALLU Transformer DL-series is designed for applications where a small and light screening bucket is required.

The DL-series make the perfect attachment for landscaping and agricultural applications. From composting to aerating, topsoil screening to waste and debris processing, all can be carried out on-site. Featuring a self-cleaning design ALLU DL buckets produce homogenous end product even with wet materials.

Suit excavators (can be mounted as backhoe or front shovel), skid steers, wheel loaders, tractors and mini excavators.

Main application areas are:

- aerating

- screening

- composting

- landscaping

- waste material handling

- pipeline padding

See the links below for features and specifications:

One ALLU – 3 Fragment Sizes

ALLU TS structure enables three different fragment sizes from the same unit. Fragment size estimation is based on the distance set by the screening comb.

The ALLU TS structure blade setup is quick and easy to change onsite allowing you to adapt the ALLU bucket for specific screening needs and making it easy to move from one screening job to another.

Due to the TS®’s self-cleaning design the best possible capacity is enabled even with wet materials. This is called as a non-clogging structure and it is available across entire TS range.

SINGLE BLADE

Single blade setup: blade sizes 8mm, 16mm, 25mm, 35mm.

DOUBLE BLADE

Double blade setup: blade sizes 16mm, 32mm, 50mm, 70mm.

TRIPLE BLADE

Triple blade setup: blade sizes 24mm, 48mm, 75mm, 105mm.

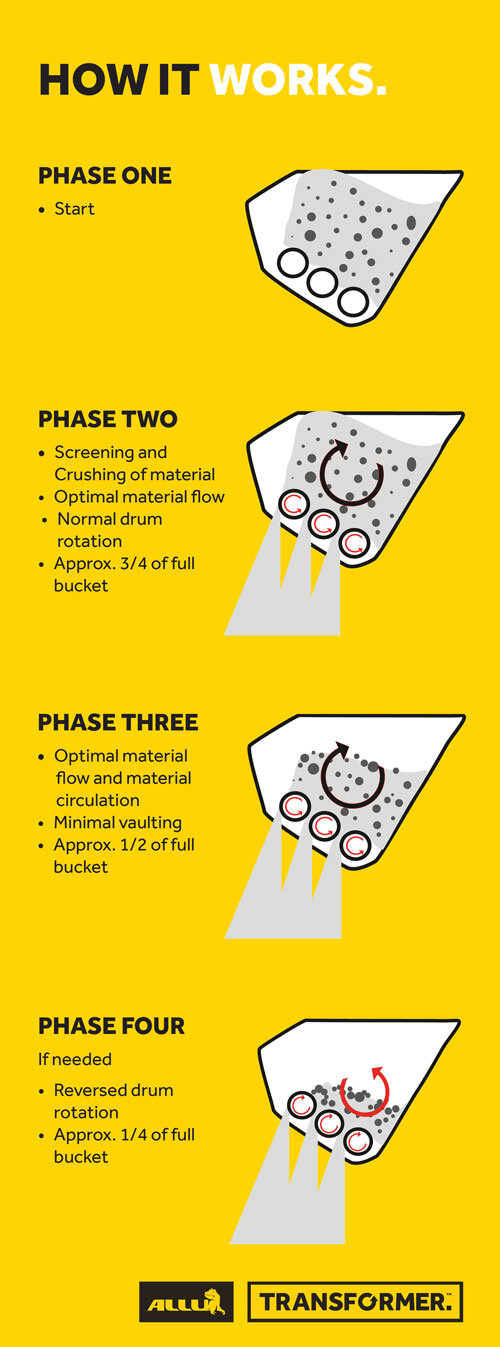

How does ALLU work?

ALLU has an unique design for bulk and mining materials handling.

- Screening and loading material

- Screening and crushing material

- Crushing soft rock material

- Re-crushing segregated material

Data Acquisition – ALLU Tracker

ALLU Tracker

Processing data is of huge value to production and financial personnel and the ALLU Transformer buckets tick that box too.

Using ALLU Tracker system, information such as:

- processed tonnes,

- bucket count,

- processing time,

- total working time,

- down time,

- cycle time and

- even hydraulic temperature

can be recorded and viewed via an easy-to-use dashboard.

The ALLU Tracker notifies about the need for maintenance or replacement of wear parts to help you minimize downtime.

By obtaining accurate and timely information on the actual throughput of the attachment help manage production schedules, estimate project finish times and provide new project quotes, just as it would be from a fixed plant.